Custom Injection Molding

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

Injection molding is not that simple as it might seems. The best part is that you have to focus on the available options as well. There is nothing to worry about when you have us by your side. We will be providing you with the best injection molding much like you have asked for. The best part about our firm is that we are not just offering standard injection molding, but now you can get custom injection molding from our side as well. It provides you with the best option when it comes to customized field in here. We will have it all covered for you.

If you are aiming for the best custom injection moulding, then you have to spend some extra bucks. When compared to the standard version, the customized moldings will cost you a bit high.

Now, it is true that you are always thinking about the quality of the custom injection mold because of the investment from your side. Well, you don’t have to worry much as the customized molds are here for you.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

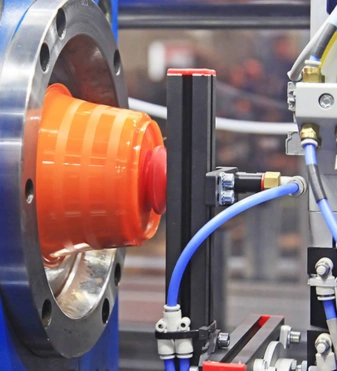

Injection Molding In Industry

We are known for some of the most cost-effective options under custom injection molding cost. So, next time you are looking for the best help, we will offer the best and reliable services within your set rates.

With us by your side, you will experience the best custom injection molding near me. We have worked with multiple clients before and helped them with the best options in town.

The component size, complexity, material, and projected volumes all play a role in deciding the custom plastic molding cost. Large runs might have high start-up costs, but as you keep producing, the cost of the project gets better and better. When calculating cost per unit, plastic injection molding is one of the most economical production processes.

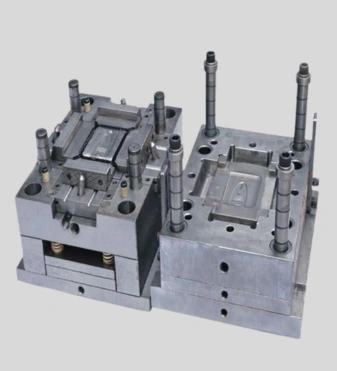

Using injection molding, the cost per unit decreases as you produce more injection molded parts using your mold. The typical price range for a tiny, single-cavity plastic injection mold is between $1,000 and $5,000. Molds that are huge or intricate may cost up to $80,000 or more. A common mold that creates a somewhat straightforward component small enough to grasp in your hand typically costs approximately $12,000. Whatever your project calls for, we can assist you in choosing between a Ferrari and a Fiat.

Pricing for any task we complete might vary significantly as we operate as a full-service plastic injection moulding products manufacturers resulting in molds from idea to completion. However, we are aware that accurate cost estimates for injection molding are essential to any project's success. To assist you in creating a budget for your mold, plastic injection molds have created the following price guide.

The choice of materials also affects how much plastic injection molds cost. For instance, the majority of typical molds will become brittle using time if an item made of plastic is manufactured using fiberglass-filled material. The only mold that can endure injection molding of material with fiberglass filler is one composed of hardened tool steel. Any project's overall plastic custom plastic molding cost must also take future operating, maintenance, and repair expenses into account.

Inform your mold builder if you have a target pricing set for your parts. To reach that pricing, they can design the custom plastic molding cost appropriately and account for the appropriate amount of cavities. Higher output is made possible by cheaper components since there are more cavities (or pieces) created every cycle. Although you don't have to be completely knowledgeable about the many kinds of molds that are out there, it's always a good idea to be ready. Your mold builder will be able to create the best tool for your project if you provide them with the fundamentals. We advise you to look for a mold manufacturer with manufacturing skills. The production business won't want to create a subpar mold since they know they must utilize it.

Countries

Industries Served

Projects

Clients

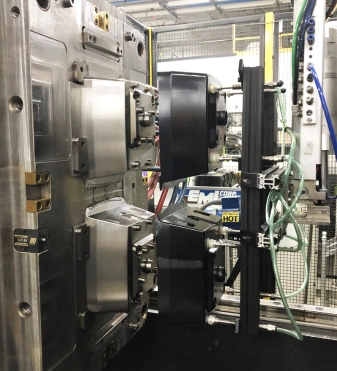

We are a fully integrated manufacturer of injection molding molds, including design, production, and sales. Injection molds, die-casting molds, tooling design services, plastic injection molding, and plastic components are our primary injection moulding products. We pursue professionalism, quality, promptness, and management. All clients may count on us to put good credit and quality first; plastic injection molds are not just a cooperator, but also your trustworthy and long-term partner.

Over the years, the business has built up the confidence and trust of many different clients and has had cordial relationships with them. Due to its great dedication to quality and reasonable costs, the firm has always held the top position in the sector. Today, several leading corporations acknowledge the business as the most reliable supplier of injection-molded products. The business is the most reputable and reliable Plastic Injection Mould Manufacturer.

Because it produces goods in large quantities at a shockingly low cost per unit, injection molding is quite common. High repeatability and considerable design flexibility are features of injection molding. Due to the high initial cost of the mold, economics is typically the biggest barrier to injection mould manufacturers. A delayed turnaround from concept to manufacturing (at least 4 weeks) is another issue.

Injection molding was used to create almost every plastic component in your environment, including kitchen appliances, electrical casings, and automotive parts. Today, both engineering and consumer items frequently employ injection molding. Almost all of the plastic objects you see around you were produced via injection molding. Due to the technology's ability to make identical components in extremely high numbers at a very cheap cost per part.

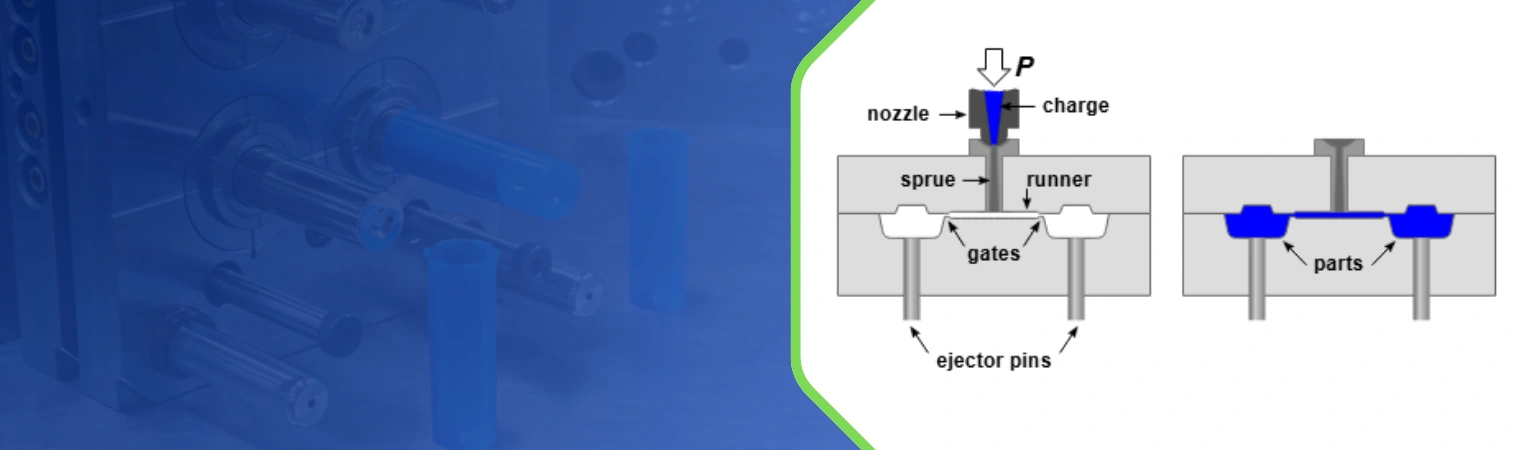

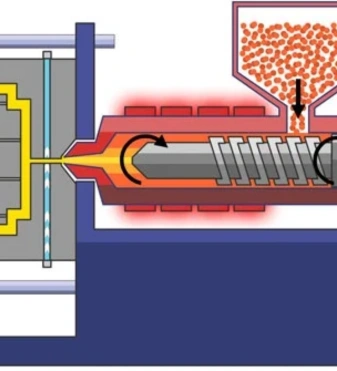

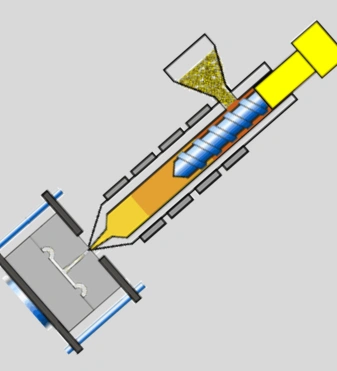

One of the top methods for producing plastics is injection molding. It is frequently used to produce identical parts in large quantities with precise tolerances. It is a highly reproducible, cost-effective process that produces high-quality parts for large-series manufacturing. To inject molten material within a mold, a quick, labor-intensive procedure involving high heat and pressure is required.

Depending on the size of the manufacturing project, the molten material may vary. The cost of injection molding, sometimes referred to as the tooling cost, is typically the largest cost factor in injection moulding near me. This indicates that the production's variable costs are low, the process becomes more effective, and the cost per part drops as production volumes increase since the expenses are spread out over hundreds or thousands of parts.

Major industrial injection molding machines, which are often run by service providers, contract manufacturers, and major manufacturers, can range from smaller desktop injection molding machines that firms can utilize internally to smaller desktop injection molding machines. More sophisticated injection moulding suppliers require technological know-how to create. As a result, businesses frequently contract out particular steps in the injection molding process, such as the design and creation of the mold.

If the technical know-how is also available, creating molds internally may be the least expensive alternative cost of injection molding for businesses that have the equipment and tools for injection molding. Outsourcing lowers the expense associated with creating a mold when the injection molding tools are not easily accessible. Depending on the material selected, the cost of acquiring materials for molds varies. The price of thermoplastic pellets varies from $1 to $5 per kilogram.

Injection molding is typically more cost-effective in bigger quantities since the expenditures are then divided over thousands of pieces. Low-volume injection molding is still much more affordable than alternative manufacturing techniques for low-volume production, notwithstanding the little higher cost per item. The most efficient for mid-volume manufacturing are machined aluminum molds, which are less expensive than conventional steel molds yet durable enough to sustain a few thousand shots depending on factors like the material and design.

Low-volume injection molding is often only practical using 3D-printed molds. The intricacy and length of time required to make the mold determine its cost in a considerable part. To reduce the cost of injection molding, we suggest adhering to design for manufacturing guidelines, plastic injection molds examine the model's design to remove any extraneous elements. This minimizes the size of the mold and the amount of material used to create the model.